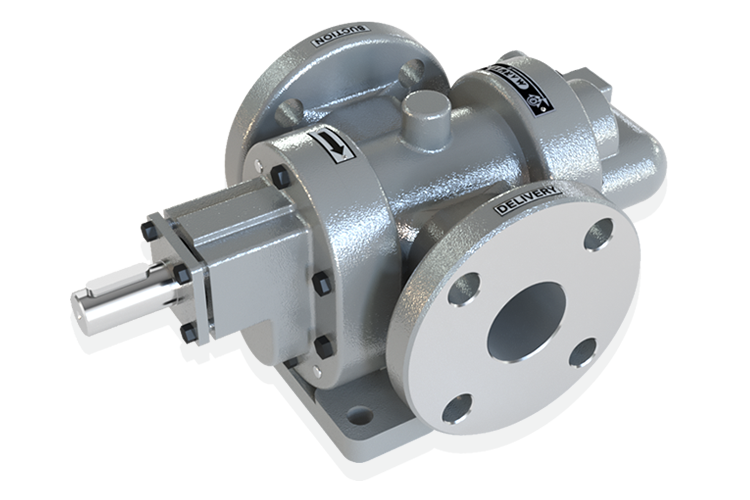

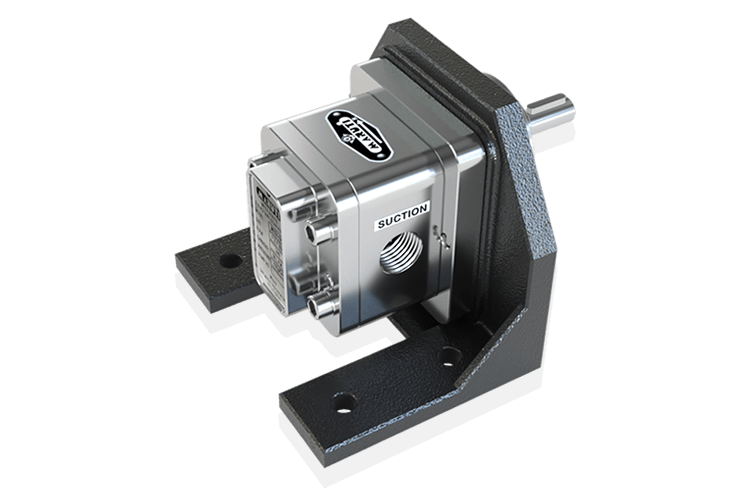

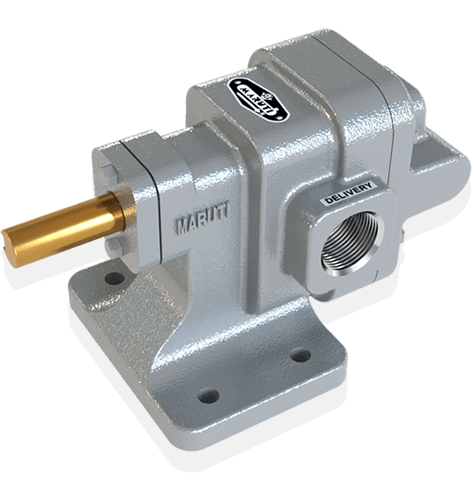

Gear Pump

A gear pump uses two gears that rotate together. As the gears turn, they trap liquid between the gear teeth and the pump casing and push it toward the discharge side. This gives a smooth, continuous, and controlled flow.

Features :

sizes: Gear pump sizes depend on flow requirement, but typical ranges are:½ inch, ¾ inch, 1 inch, 1.5 inch, 2 inch, 2.5 inch

2. Capacity

Gear pumps are known for accurate and consistent flow.

Flow Rate:

5 LPM to 500 LPM

(Higher flows possible in industrial models)

Pressure:

Up to 10 bar (standard)

Up to 20–25 bar (heavy-duty models)

Common features of gear pump construction:

Positive Displacement Type

Two Meshing Gears:

Driving gear

Driven gear

Casing with tight tolerances for smooth operation,Bearings / Bushings,Mechanical seal or gland packing,Close-coupled or base-mounted design,Self-priming capability,Bi-directional flow optional.

Materials: These pumps are available in various materials of construction, including metals like aluminum, stainless steel, and plastics like polypropylene.

Gear pumps are widely used for transferring viscous and lubricating liquids.Industrial Applications,Hydraulic oils,Lubrication oil systems,Gear oil, engine oil,Furnace oil, light & heavy fuel oil