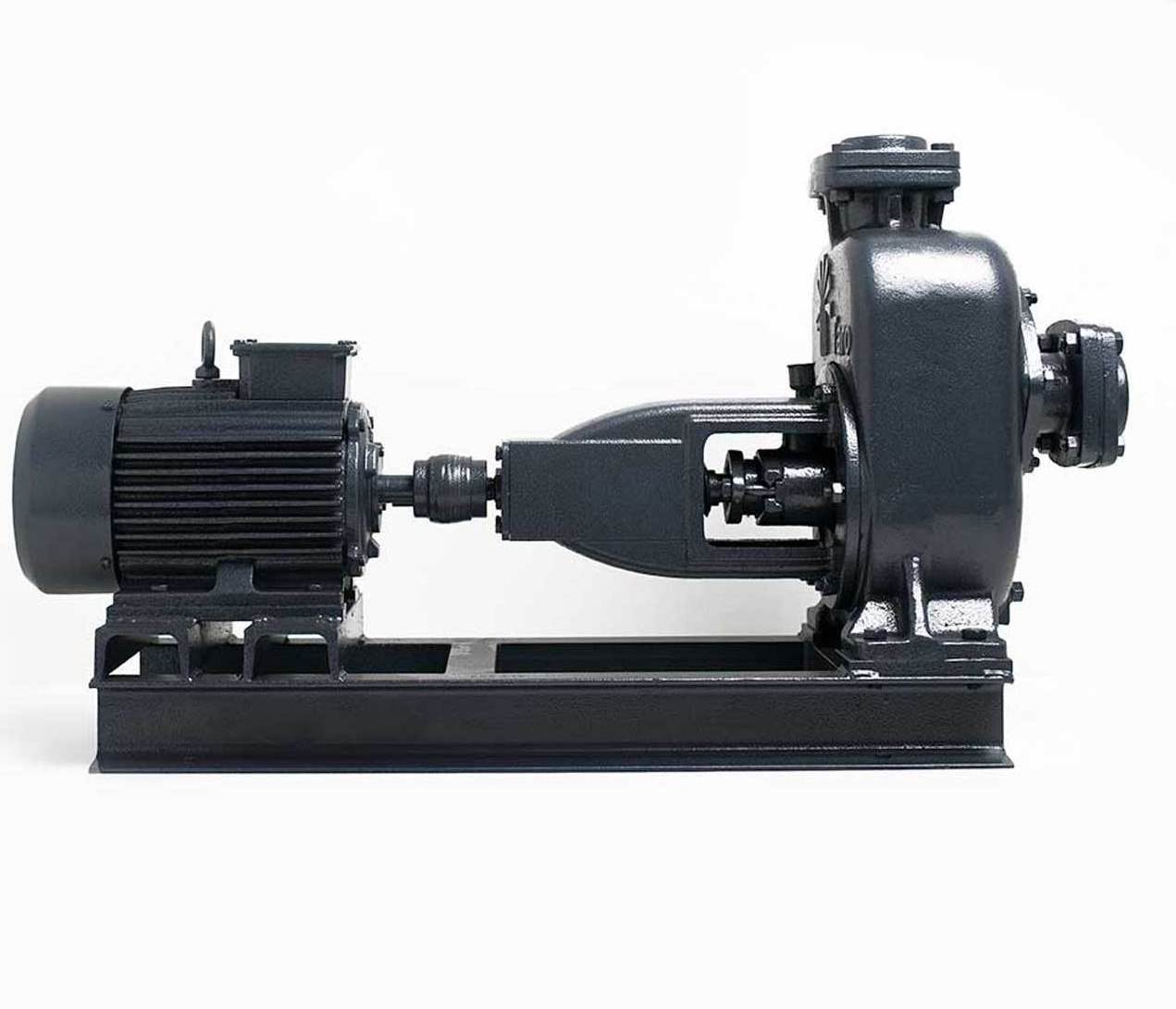

Sewage Pump

A Sewage Pump is designed to transfer dirty water, wastewater, sludge, and solids from pits, drainage systems, septic tanks, and sewage treatment plants. These pumps can handle solids, fibers, and contaminated liquids that normal pumps cannot.

Features :

Size: Sewage pump sizes depend on solids-handling capacity and flow requirement. Typical Size Range like 50 mm (2 inch), 65 mm (2.5 inch), 80 mm (3 inch), 100 mm (4 inch), 150 mm (6 inch). Solids Handling Capacity 25 mm to 100 mm solids (depending on impeller type).

Capacity:Flow Capacity

5 m³/hr to 500 m³/hr

(large models go up to 1000 m³/hr).

Head / Pressure

5 meters to 50 meters.

Motor Power

0.5 HP to 50 HP

(Submersible sewage pumps mostly 1 HP to 20 HP

Operating Type

Submersible

Non-clog surface pump

Cutter pump (for cutting solids)

Construction:

Working Principle

A sewage pump uses a non-clog impeller that allows solids to pass without blocking.

Key Construction Features

Non-clog impeller (Vortex / Cutter / Channel type)

Submersible motor sealed against water

Double mechanical seal

Heavy-duty bearings

Stainless steel or cast iron body

Cable with waterproof sealing

Materials: These pumps are available in various materials of construction, including metals like aluminum, stainless steel, and plastics like polypropylene.

Applications: Municipal / Industrial Use

Sewage treatment plants (STP)

Effluent treatment plants (ETP)

Sludge transfer

Wastewater pumping

Drainage systems