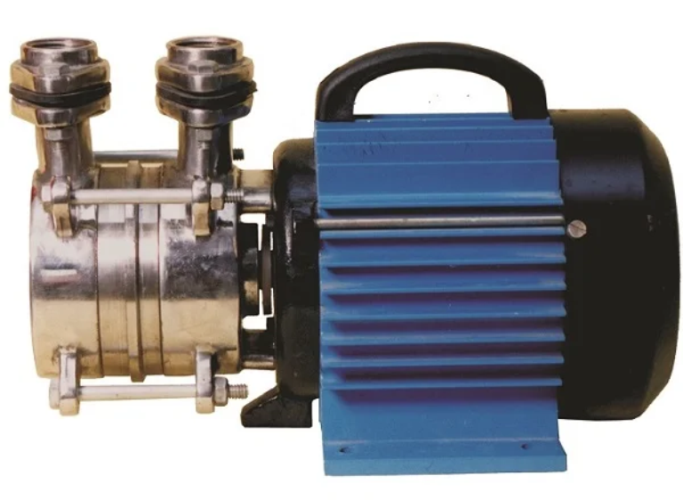

SS Centrifugal Pump – High-Performance Stainless Steel Industrial Pump

Our SS Centrifugal Pump is engineered for superior efficiency, durability, and hygienic fluid transfer across a wide range of industrial applications. Manufactured from high-grade Stainless Steel SS304 / SS316 / SS316L, this pump delivers exceptional corrosion resistance, smooth operation, and long service life even under continuous-duty conditions.

Designed to handle clean water, mild chemicals, solvents, food-grade liquids, and pharmaceutical media, our stainless steel centrifugal pump ensures hygienic, contamination-free, and reliable performance in every application.

Production Details:

The Stainless Steel Centrifugal Pump is built using precision-machined components and a hydraulically efficient impeller that ensures consistent flow, minimal vibration, and low energy consumption. Its premium stainless-steel construction makes it ideal for applications requiring high purity, hygiene, and resistance to corrosive fluids.

With a back-pull-out design, maintenance becomes effortless, allowing seal replacements or rotor inspections without disconnecting the pump from the pipeline. The internal surfaces are polished to minimize friction, prevent bacterial growth, and ensure optimal flow characteristics.

This pump is widely used in the food & beverage, pharmaceutical, water treatment, chemical processing, dairy, and general industry due to its clean design and robust performance.

⚙️ Technical Data (Specifications)

Construction Material

| Component | Material |

|---|---|

| Pump Casing | SS304 / SS316 / SS316L |

| Impeller | SS304 / SS316 / SS316L |

| Shaft | SS304 / SS316 |

| Seal | Adjustable 0–100% |

| SMechanical Seal (Carbon/SiC/TC) | 10–150 strokes/min |

| Gasket | PTFE / EPDM |

| Base Frame | MS Painted / SS Optional |

Performance Range

| Parameter | Specification |

|---|---|

| Flow Capacity | Up to 150 m³/hr |

| Head | Up to 60 meters |

| Speed | 1450 / 2900 RPM |

| Operating Temperature | 0°C to 120°C |

| Operating Pressure | Up to 10 bar |

| Viscosity | Up to 200 cSt |

| Connection Type | Flanged / Threaded |

Features :

• Horizontal, single-stage, end-suction design

• High-efficiency stainless steel impeller

• Back-pull-out system for easy maintenance

• Smooth internal finish for hygienic flow

• Leak-proof mechanical sealing system

• Energy-efficient hydraulic performance

• Options for close-coupled or bare-shaft design

💡 Key Features & Benefits:

• 100% stainless-steel wetted components

• Excellent corrosion & rust resistance

• Hygienic and contamination-free operation

• High flow & high efficiency

• Smooth, vibration-free performance

• Long service life with minimal maintenance

• Suitable for hot, cold, and mild viscous fluids

• Available in multiple grade options (SS304 / SS316 / SS316L)

📦 Optional Accessories:

• VFD (Variable Frequency Drive)

• SS Base Frame

• Tri-Clamp Sanitary Fittings

• Flameproof / Weatherproof Motors

• Pressure & Temperature Monitoring Instruments

Benefits at a Glance:

• 100% stainless steel wetted components

• High flow, high efficiency, and stable operation

• Low maintenance cost and long service life

• Hygienic fluid transfer without contamination

• Versatile design for multiple industrial sectors

• Suitable for both corrosive and hygienic environments

🏭 Applications:• Food & Beverage Processing

• Pharmaceutical & Biotech Industries

• RO / DM / Water Purification Systems

• Light Chemical Transfer

• Dairy Plants, Breweries & Distilleries

• Cosmetics & Personal Care Manufacturing

• Solvent, Oil & Alcohol Circulation

• General Industrial Fluid Transfer